Description

Model Specifications

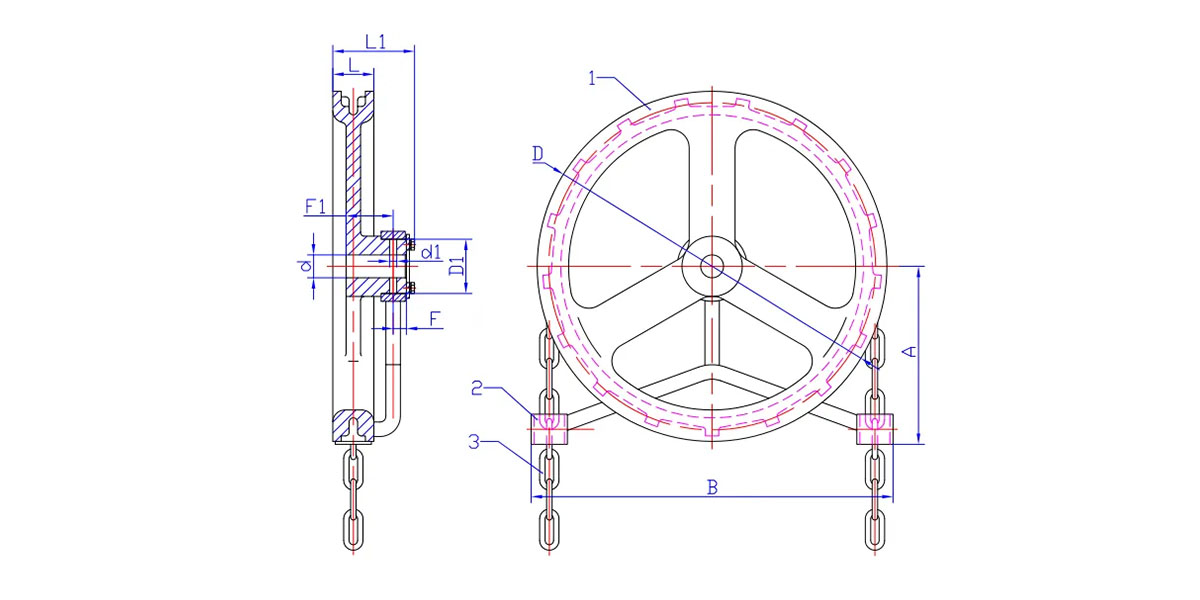

| Model | d | D | D1 | L | L1 | A | B | F | d1 | Pin | F1 |

| 135 | 16 | 135 | 45 | 29 | 66 | 72 | 145 | 11 | 6 | 6×40 | 39 |

| 200 | 16 | 200 | 45 | 34 | 68 | 105 | 210 | 11 | 6 | 6×40 | 39 |

| 290 | 19 | 290 | 45 | 34 | 68 | 147 | 300 | 12 | 8 | 6×40 | 41 |

| 410 | 25 | 410 | 55 | 38 | 73 | 197 | 410 | 12 | 8 | 8×50 | 42 |

| 574 | 25 | 576 | 60 | 42 | 76 | 266 | 570 | 12 | 8 | 8×50 | 42 |

Parts and Materials

| Serial No. | Parts | Material | Optional Material 1 | Optional Material 2 |

|---|---|---|---|---|

| 1 | Chain wheel | Ductile Iron 450-10 | CF8 | CF8M |

| 2 | Bracket | Carbon Steel | SS304 | SS316 |

| 3 | Chain | Carbon Steel | SS304 | SS316 |

Chainwheel for Manual Valve Operation

We are supplying chainwheel of Stainless Steel, Carbon Steel, Galvanised, Ductile Iron and Customized Chainwheel to our high quality standard.

Galvanised Chainwheel

Sometimes especially harsh operating environments wil necessitate an extra level of protection for chainwheels. Many chainwheels are used in the petrochemical industry, where they are exposed to chemicals, extreme temperature or humidity. In such cases, we are supplying galvanized chainwheels to extend the life of the product in corrosive environments. Galvanizing is also ideal for high moisture environments (such as offshore or marine) where corrosion resistance is important.

Stainless Steel Chainwheels

Especially harsh operating environments sometimes necessitate an extra level of protection for chainwheels. Many chain wheels are used in the petrochemical industry, where they are exposed to chemicals, extreme temperature or humidity. In such cases, we offer stainless steel chainwheels to extend the life of the product in corrosive environments.

Stainless steel is also ideal for high moisture environments (such as offshore or marine) where corrosion resistance is important.

Customized Size or/and Paint Chainwheel Customized Size or/and Paint Chainwheel are available for your chainwheel to match your facilities.

Reviews

There are no reviews yet.